Components for landing gears

Acosur ZNA for fasteners, which are exposed to corrosion, as a substitute for cadmium coatings in the landing gear area.

Components for landing gears

Acosur ZNA for fasteners, which are exposed to corrosion, as a substitute for cadmium coatings in the landing gear area.

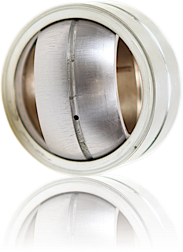

Spherical plain bearings

Excellent corrosion resistance and high adhesion to stainless steels make Acosur ZNA the ideal replacement for cadmium coatings.

Specifications

‣color:

‣temperature range:

‣layer thickness:

‣corrosion protection:

‣processing temp.:

‣techn. conformity:

‣HSE conformity:

Coatable materials

‣Ferrous and non ferrous metals with UTS<1450 MPa

‣high-alloy steels

‣hardened steels

‣all standard bearing materials can be coated, including: 100Cr6, 100CrMn6, 100CrMo6, 440C, X65Cr13, X30CrMoN15-1

‣grey to yellowish brownish

‣-55 - 180 °C

‣10-18µm or as specified

‣> 750 h, RR (ISO 9227)

‣room temp.

‣AIPS 02-04-006, AMS 2417

‣RoHS, WEEE, REACH, 2000/53/EG

Characteristics

Ordering information

AIPS 02-04-006 conform:

Acosur ZNA xx-xx y z

‣xx-xx:

‣y:

‣

‣z:

‣Layer thickness range in micron

‣1 - hydrogen de-embrittlement

‣0 - no de-embrittlement

‣1 - as plated

‣2 - subsequent passivation (Cr 3)

for bearing parts:

Acosur ZNA 01-03 02

‣Layer thickness 1-3 µm, Cr6-free passivated

Did you know ?

The cadmium replacement for Aerospace

Acosur® ZNA is a modified electroplated zinc-nickel alloy coating. It is characterized by excellent adhesion and high corrosion protection and also meets the requirements of Airbus AIPS 02-04-006, AMS 2417 as well as prEN 4826.

Thus, Acosur ZNA is a contemporary substitute for conventional aerospace anti-corrosion coatings like cadmium or chromium VI-containing zinc coatings.

Features

The ability to coat even high alloy stainless steels and materials, combined with a layer thickness of 1-3 microns, makes Acosur ZNA inter alia, the ideal coating process for bearing components.

Designed for versatile use

A wide range of layer thicknesses and the possibility to coat high-alloy steels guarantee a wide range of applications.

Examples

Bearing parts

Thin films and very high corrosion protection make Acosur ZNA the ideal replacement for cadmium coatings on bearing components.

Resistance

‣not acid-resistant

‣resistant to lubricants, fuels and solvents

Environment & Safety

Acosur ZNA does not

contain any hazardous

substances for humans or

environment.

RoHS compliant

REACH compliant

WEEE compliant

Acosur ZN05A in corrosion test

Uncoated after 24 hours in salt spray test.

Acosur® type ZNA coated after 500 hours salt spray test.

results are dependent on general geometry

Test method: neutral salt spray test according to DIN EN ISO 9227

MBK Coatings

Acosur ZNA

Decorative coating

for high-quality tools

Unique dry lubrication for

bearings.

Corrosion protection without cadmium for Aerospace applications.

Dry lubrication coating

für high temperature applications

Technical datasheet

| EN 9100 | AEROSPACE