Wolfratherm

Proven 100.000+ times for use in vacuum pumps.

Wolfratherm

Proven 100.000+ times for use in vacuum pumps.

Wolfratherm

Ideal for use in

Aerospace applications

Wolfratherm

Ideal for use in

coating equipment

for optical lenses

Did you know ?

Designed for the highest standards.

Wolfratherm ® is a proven, outstanding permanent dry lubrication for bearings on basis of the solid lubricant MoS2. An optimal binding and anchoring of MoS2 is supported by a galvanically applied multilayer system.

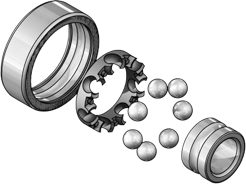

How it works.

The Wolfratherm ® coating of your bearing parts is conducted in our house. Individual components such as outer ring, inner ring and cage components are individually coated in a multi-stage process. Then these parts are assembled together with the non-coated balls by the manufacturer of the rolling bearings.

Technical datasheet

The layer structure is approximately 5μm and provides an improved corrosion protection, compared to the uncoated parts.

Almost all major bearing types and sizes including miniature bearings can be coated.

Wolfratherm in vacuum

Speeds ranging from 10000-100000 rpm are a particular challenge for the lubrication of bearings.

In turbo-molecular pumps, Wolfratherm has therefore proved itself thousend of times as a life-dry lubrication and lifetime extension.

Wolfratherm in optics

Coatings of optical glasses in the vacuum by PVD or CVD processes prohibit the use of oils or greases in rolling bearings.

Wolfratherm as a dry lubrication has proved itself as an excellent lifetime extension in such cases.

Proven for special applications.

The areas of Wolfratherm range from turbo-molecular pumps over coaters for optical glasses up to the aerospace or cryogenic technology.

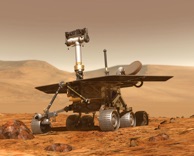

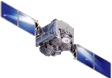

Wolfratherm in space

Low temperatures and vacuum, these are the challenges for lubrication tasks in space.

Solar panels for satellites, but also parts of the Mars Rovers were therefore coated with Wolfratherm.

Specifications

Characteristics

‣ temperature range:

‣ speed factor:

‣ precessing size:

‣ layer thickness:

‣ color:

‣ conformity:

Resistance

‣up to 90% rel. humidity, no aqueous condensation allowed.

‣not acid-resistant.

‣resistant to lubricants, fuels and solvents.

Clearance

‣C3 recommended

Examples

Order information

Features

Wolfratherm

MBK Coatings

-200 bis 350°C

600 000 mm min-1

Bearings with D > 3mm

5 µm

metallic gray

RoHS, WEEE, REACH

Environment & Safety

Wolfratherm does not

contain any hazardous

substances for humans or

environment.

RoHS compliant

REACH compliant

WEEE compliant

This coating is useful if there is a lubrication with grease or oil not possible, desirable or acceptable. Examples are roller bearings, which are installed at low and high temperatures, within vacuum, within radiation or due to the risk of fogging in optical systems.

Decorative coating

for high-quality tools

Unique dry lubrication for

bearings.

Corrosion protection without cadmium for Aerospace applications.

Dry lubrication coating

für high temperature applications

| EN 9100 | AEROSPACE